Inventory Management for Production Materials - Books&Co.

As we've seen in the chapter dedicated to production, inventory management can significantly impact company results.

First and foremost, it's necessary to ensure a constant flow of materials to meet production needs. In econoPy, you can manage this aspect by selecting the reorder point (the percentage of inventory below which an automatic replenishment order is sent to the supplier) and the reorder quantity (the amount ordered).

Orders will be placed based on selected criteria: quality, delivery times, payment terms, environmental sustainability, and supplier reputation. The order price will be dynamically generated based on these factors. The price increases with higher: quality, payment terms, supplier reputation, and sustainability. The price increases with lower: quantity and delivery days.

Important: At the time of order, the company must pay an advance on the order value. This often occurs to reduce the risk of insolvency.

Therefore, if the company lacks the liquidity to guarantee the advance payment, the order will not be sent!

Balancing Reorder Point, Reorder Quantity, and Delivery Times

In general, we can pursue two types of strategies:

Low Inventory Level

In this strategy, the company seeks to minimize capital invested in materials. Both the reorder point and quantity are low, but in this case, delivery times must be fast. This strategy is particularly used by companies with limited financial resources, productivity, and storage capacity willing to accept an increase in unit production cost.

Advantages:

- Low capital tied up in inventory

- Higher probability of having liquidity to pay the advance

- Lower investments in warehousing and storage capacity (rent, insurance, logistics management)

Disadvantages:

- The average unit cost of inventory will be higher, negatively impacting the unit cost of the finished product

- Shipments always carry a risk of delay, which can lead to moments when the warehouse is out of materials and production will be zero. This can severely impact unit production cost and sales order fulfillment, affecting revenue and reputation.

High Inventory Level

In this strategy, the company seeks to reduce unit costs and the risk of production interruption. By placing large orders, the purchase cost of inventory will be lower as the company has more bargaining power, allowing for favorable economies of scale. Delivery times, in this case, can be slower as the company can rely on existing inventory, and potential delays of 1-2 days can be absorbed without interruptions in production. This strategy is particularly used by large companies with high productivity, spacious warehouses, and sufficient financial resources, where the goal is to reduce the unit production cost as much as possible.

How Other Factors Impact Inventory Management

Quality

The quality of raw materials determines the quality of the finished product.

Important: You cannot generate quality from nothing!

Another important aspect is the presence of waste. Low-quality materials often have imperfections and are therefore discarded as unsuitable for production. This means we will need more materials, resulting in higher costs.

Supplier Reputation

Consequently increases the company's reputation and the quality of the production process.

Environmental Sustainability

In addition to being an ethical duty of the company, it also increases reputation in the eyes of customers.

Payment Terms

Longer payment terms are certainly favorable for cash flow but could result in higher order costs as the supplier might want to protect themselves from risk with a surcharge.

Books&Co Inventory Management Example

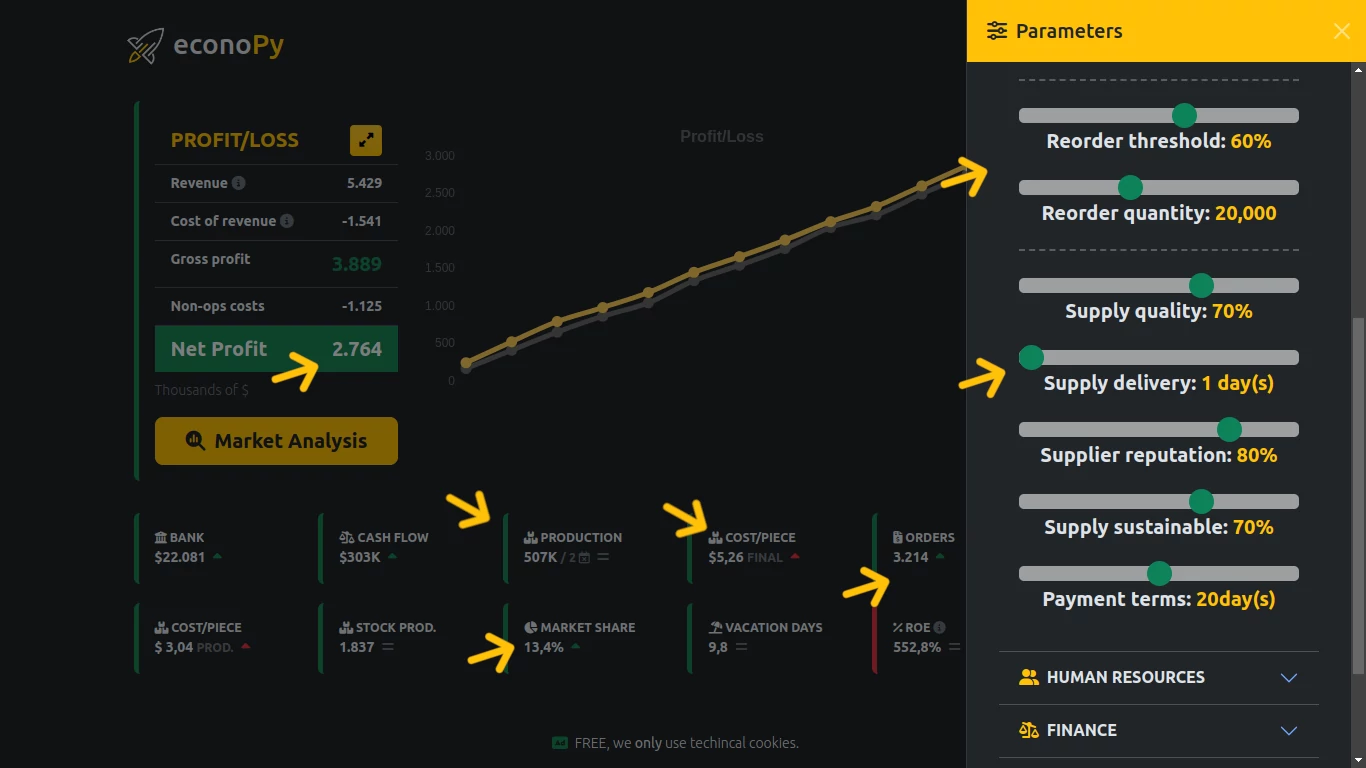

- The reorder level is 60%, and the quantity is 20,000 units.

- Quality: 70% (medium-high)

- Delivery time: 1 day (fast)

- Reputation: 80% (high)

- Environmental sustainability: 70% (medium-high)

- Payment terms: 20 days (standard)

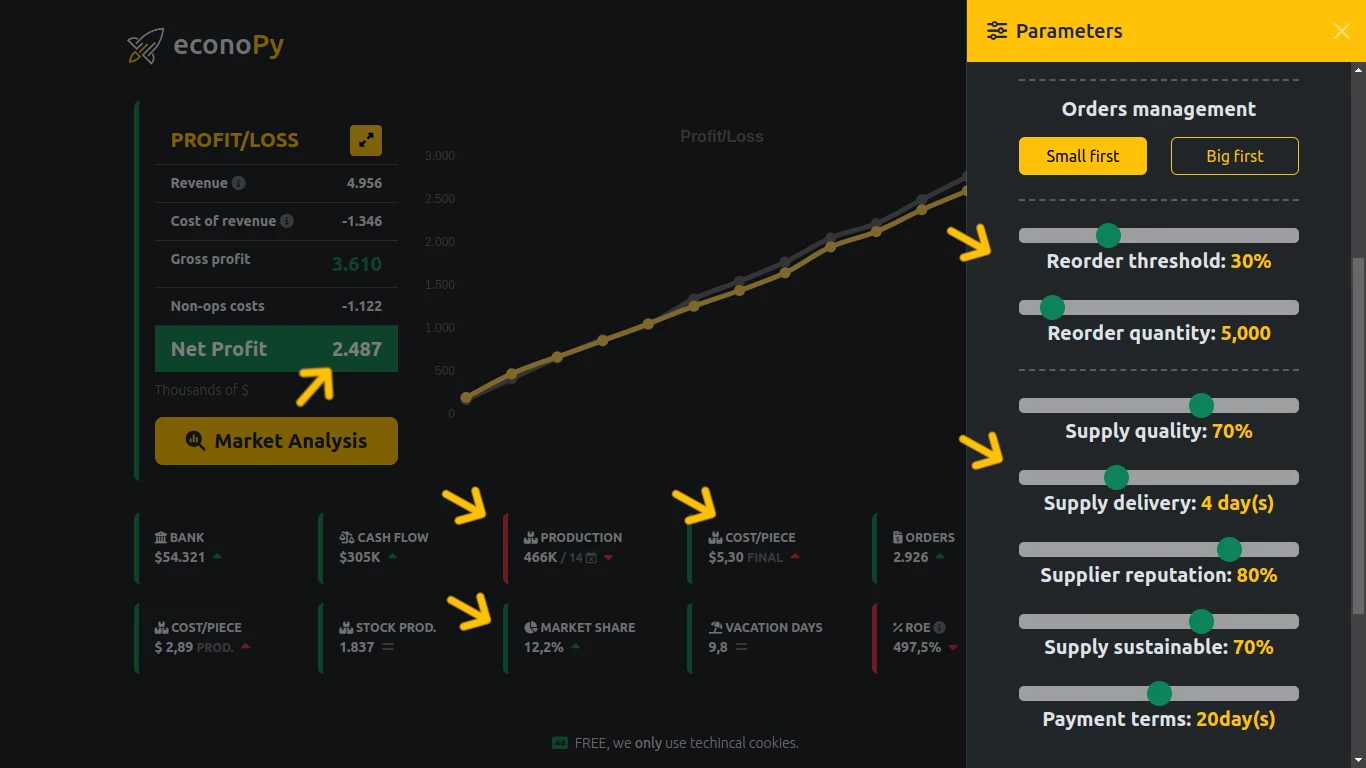

Books&Co decides to reduce investment in inventory and changes its inventory strategy as follows:

- Reorder level from 60% to 30%

- Order quantity from 20,000 to 5,000

- Delivery times from 1 to 4 days

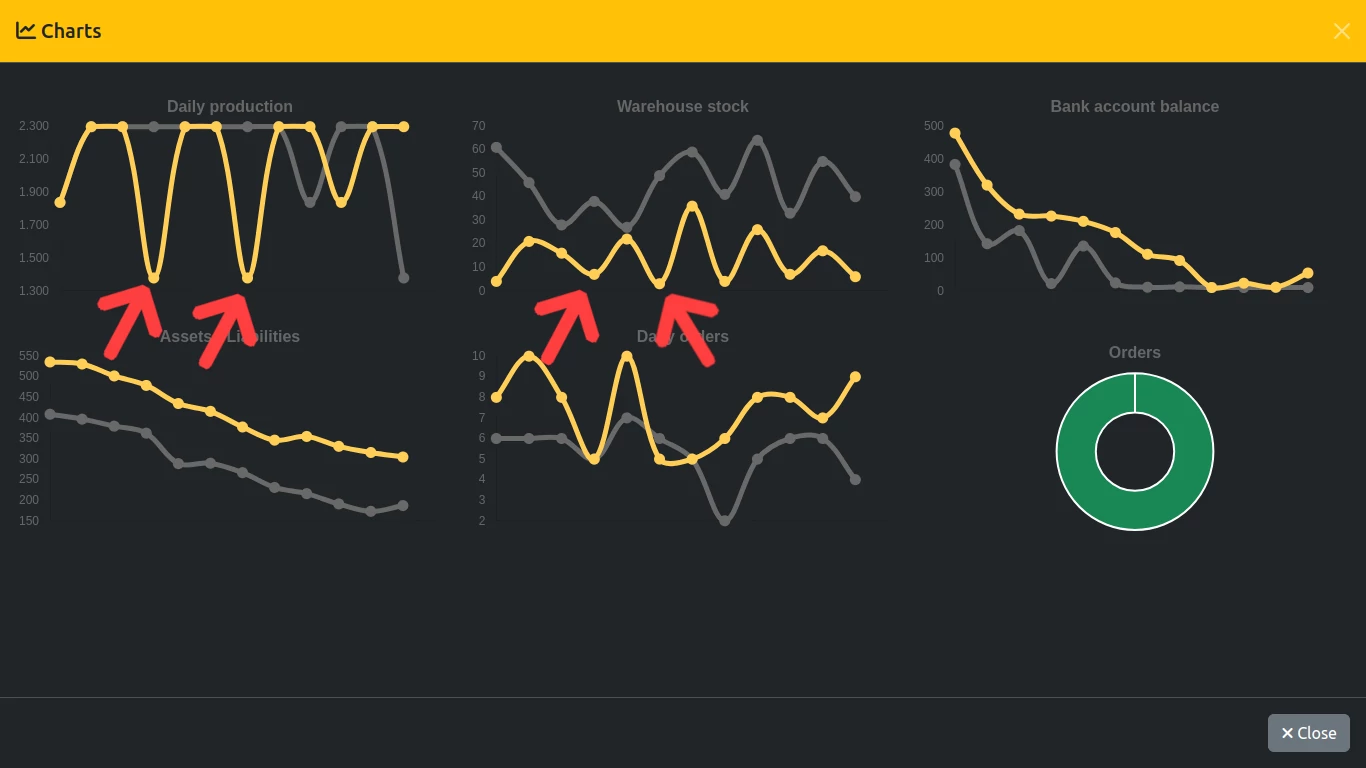

The result of this choice leads Books&Co to have days where the absence of inventory forces production interruption. This negatively impacts sales order fulfillment, market share, production cost, and profitability.

Try varying the parameters to find the right balance, but remember that these values are not universal and should always be related to productivity! By hiring more staff, purchasing new machines, or applying a more aggressive sales pricing policy with a consequent increase in orders, you will need to modify the inventory strategy accordingly!

In this case too, doing business is solving a sizing problem!

Summary

Inventory management plays a fundamental role in company results. Particular attention should be paid to the reorder strategy to find the right balance between investments and production.

Keywords: inventory management, production efficiency, reorder strategy, supply chain optimization, business performance, cost reduction, stock control, inventory levels, supplier management, production planning, econopy, manufacturing best practices, inventory turnover, operational efficiency, supply chain management.